Precautions for installation and use of silicone sealing rings

Among numerous sealing rings, silicone sealing ring is the best. It has the characteristics of being odorless, non-toxic, not afraid of high temperatures, cold resistant to ℃ and minus 90 ℃, "calming", "calming", and still will not lose its original strength and elasticity. The silicone sealing ring also has functions such as electrical insulation, oxygen resistance, light resistance, mold resistance, and chemical stability. The application range is very wide, and the market development prospects are very broad. The following article mainly introduces the installation and use of silicone density.

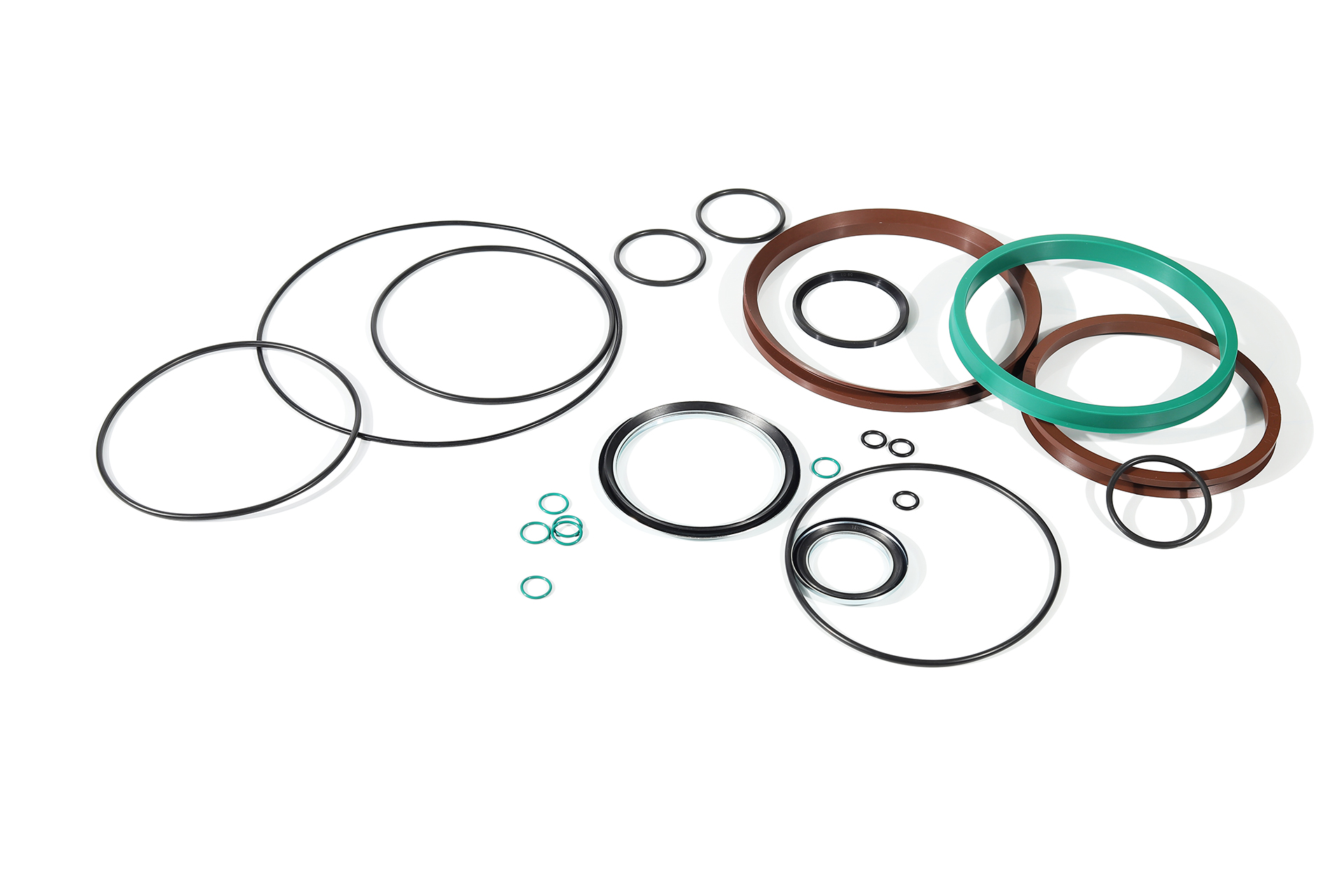

We can provide one-stop sealing solutions according to customers' needs.

Question 1: Please pay attention to the direction of the sign during installation. If the direction is incorrect, it cannot be installed. There may be a problem when pressing the button. The edges may be damaged, causing air leakage, leakage, and damage.

Question 2: After installation is completed, preliminary testing should be conducted to see if the installation is correct. For example, avoid using heat-resistant silicone sealing rings when the temperature is too high during use.

Problem 3: The quality of silicone sealing rings needs to be strictly inspected. Different sealing rings have different application products and cannot be replaced arbitrarily. According to the dimensions and specifications specified in the manual, old sealing rings that have not been replaced with the same size must be used.

Question 4: Before replacing the installation and sealing ring, special tools should be used to disassemble and clean the internal components to ensure cleanliness and hygiene.

During the installation process of the silicone sealing ring, it is important to pay attention to the above four issues. At the same time, when upgrading silicone sealing rings, it is also important to note that each sealing ring corresponds to different finished products and uses. For example, heat-resistant silicone sealing rings are mainly used for sealing electrical, crude oil, and other storage containers. The operation must be carried out according to the rules.

CRGS

CRGS 2023-08-10

2023-08-10