Formula and design of O-ring rubber material

Formula and design of O-ring rubber material

The formula and design of O-ring rubber mainly depend on the application scenario and specific requirements. The following are some general formulas and design principles for O-ring rubber:

Basic raw materials

Silicone: It is a commonly used basic raw material for O-ring rubber, with good elasticity and chemical resistance.

Carbon black: It is a commonly used black pigment that can improve the heat resistance and wear resistance of rubber materials.

Sugar: It can adjust the viscosity and fluidity of rubber materials, commonly used include sucrose, glucose, etc.

Oil: It can adjust the fluidity and plasticity of rubber materials, commonly used include gasoline, kerosene, etc.

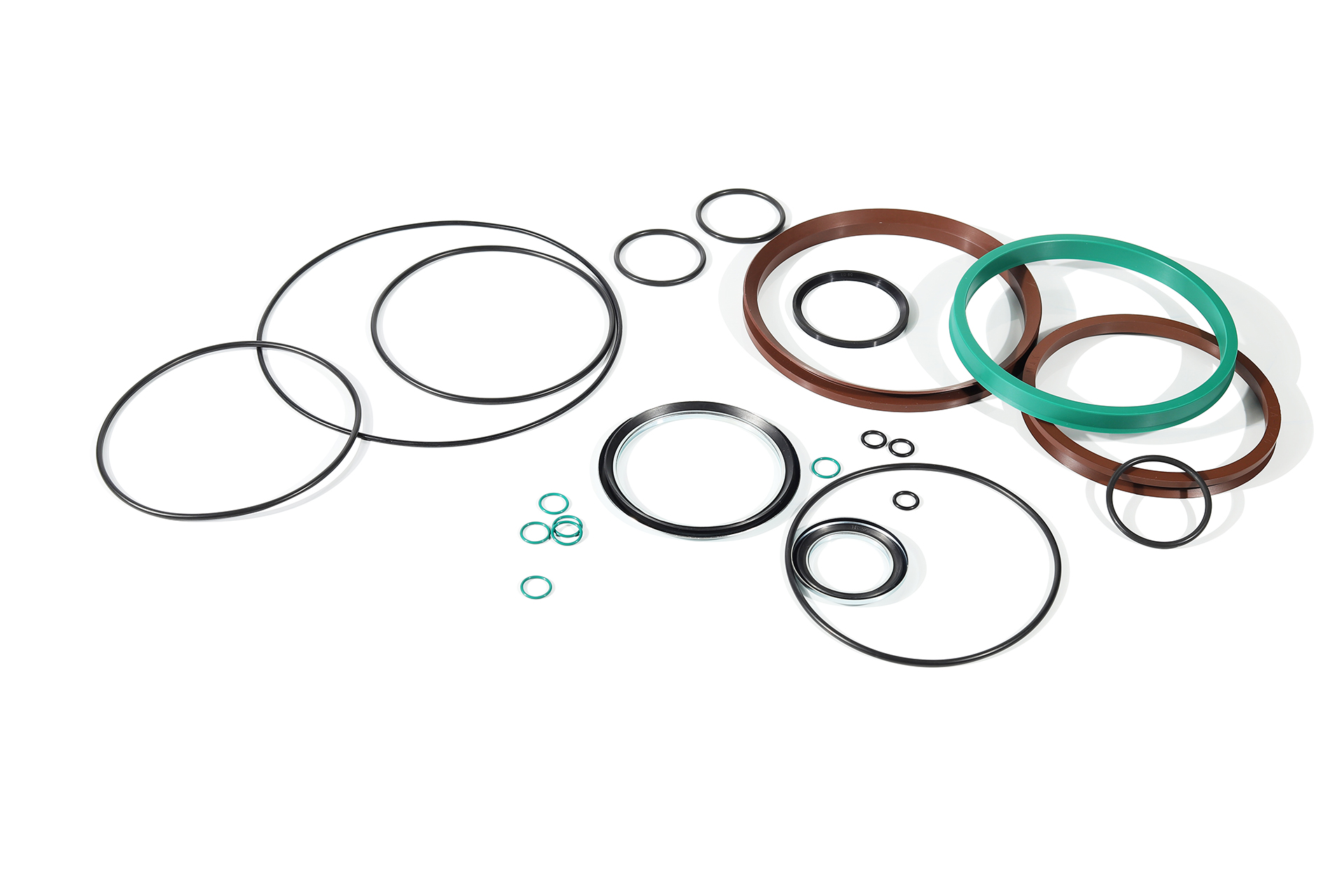

We can provide one-stop sealing solutions according to customers' needs.

Formula design principles

Ensure the strength and durability of the adhesive material to meet the usage requirements of the O-ring.

Ensure the heat and chemical resistance of the adhesive to adapt to different application scenarios.

Adjust the viscosity and flowability of the adhesive to meet different application needs.

Minimize environmental pollution and waste to achieve sustainable production.

Practical application cases

The O-ring adhesive used for electronic components needs to have good heat and chemical resistance, generally using raw materials such as silicone, carbon black, sugars, and oils, and adding an appropriate amount of antioxidants and anti-aging agents.

The O-ring compound used for automobile braking system needs to have good strength and wear resistance. Generally, silica gel, carbon black, sugar, oil and other raw materials are used, and an appropriate amount of anti-aging agent and antistatic agent are added.

CRGS

CRGS 2023-05-23

2023-05-23